It has been said that all naval aircraft for aircraft carrier use after the War had to fold up into the same width as a Seafire – because that determined the available lift size. Is this true?

Well, maybe not quite, but similar considerations apply to the question of the AW101 and its use of three engines.

Conceptual Design Background

To discuss this question it is worth considering how the conceptual design process works. First, the customer (through the Operational Requirement staff and with Defence Equipment & Support (or MoD PE, as it was then)) identifies a capability gap and commissions preliminary feasibility or concept studies to look at options for addressing this gap.

These options will investigate different technology options to determine what potential solutions could be available to meet the capability requirements within the required timescale at an acceptable cost and risk. (In this instance, Multi-Role Fleet Helicopter; Sea King Replacement; and WG34 (also known as SKR Option 5) studies).

The diagram below gives some idea of the subsequent process. The ‘Requirements & Constraints’ at this early stage are likely to be expressed in terms of a Target. Later on as the project matures, this will harden into a Requirement (used as the basis of a competition to down-select a contractor for the development phase).

Once the solution has been selected for development, that work and the subsequent acceptance of the design will be against a contractually-binding specification.

Operational analysis is used in this process to analyse the Concept of Operation at the system level. OA and trade studies are used to identify how changes in technology influence the effectiveness of individual sub-systems and system attributes (such as manoeuvrability, survivability, detectability, threat detection and prosecution, flight performance, environmental limitations, etc). Parametric cost assessments and risk analysis then allow optimisation in terms of cost effectiveness.

Physical integration (packaging) is likely to set hard constraints on some elements of the system and generally requires design activity (i.e. drawing of the system solution – nowadays on a CAD system).

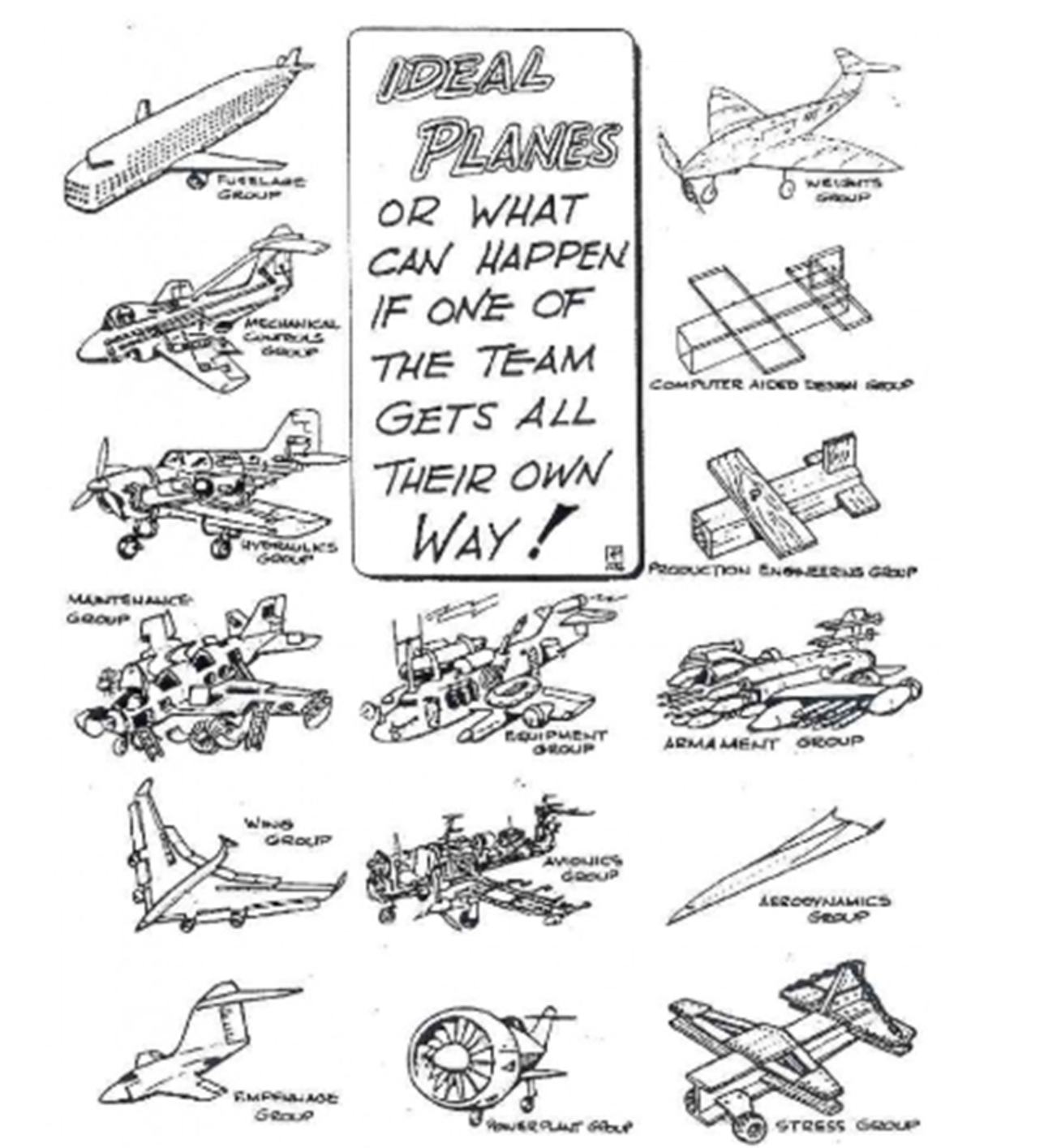

Effects of a ‘stove-piped’ view

Now, each specialist area tends to have a strong view of how the project should emerge, based on their specific perspective. (We must use this new armour, the radar signature requires these strategies etc. This results in the sort of cartoon reproduced below:

It is the job of the Head of Projects, or the Configuration Team to make sensible cross-system trade-offs to produce a solution which, if not ideal, is acceptable to all.

Naval helicopter design drivers

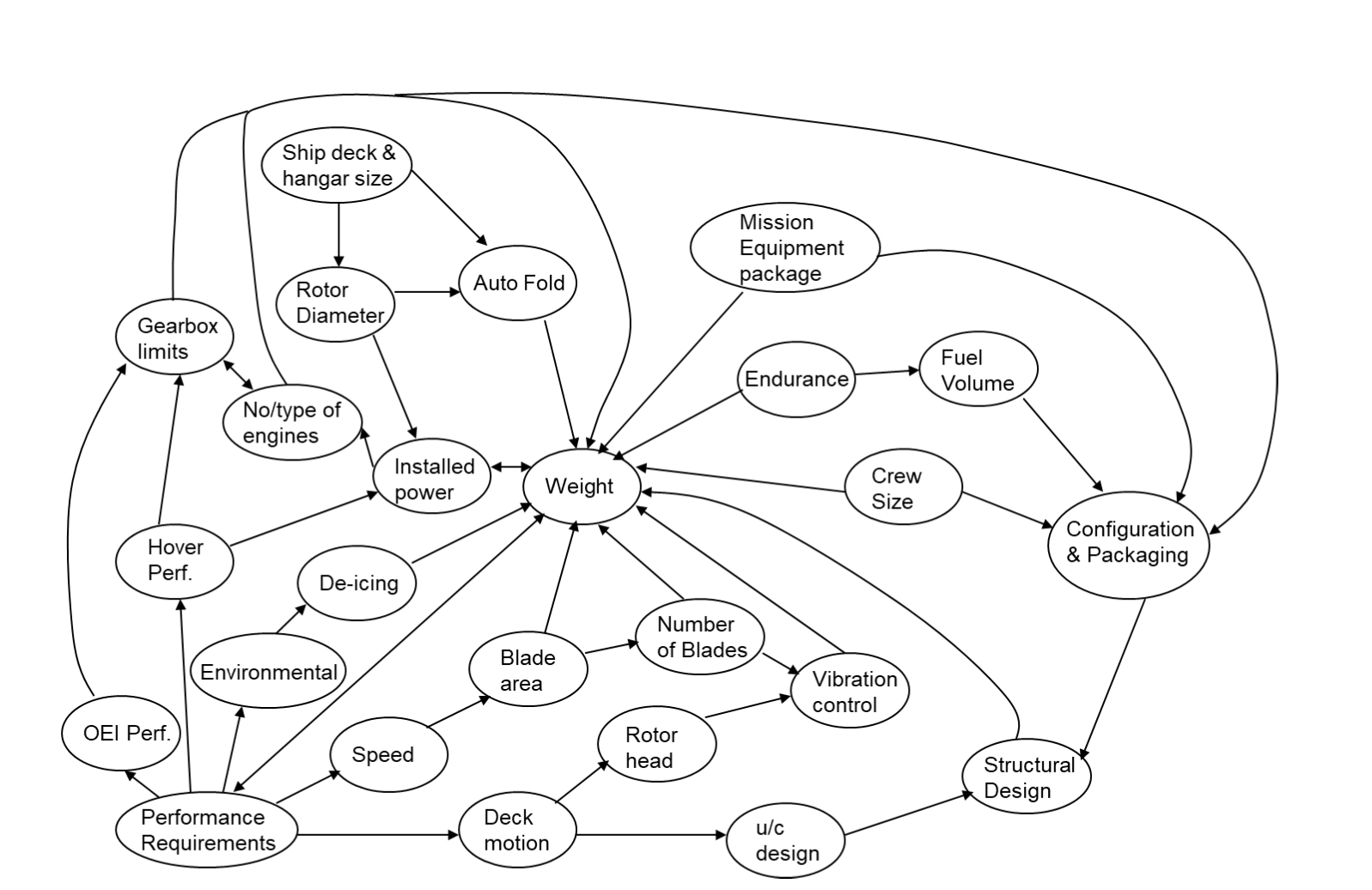

In the instance of AW101, it is useful to consider the ‘influence diagram’ below, which gives some idea of how specific requirements and factors influence the design solution of a naval shipboard helicopter.

In looking at this diagram, it is instructive to consider how many aspects of the design and the underlying requirements end up driving the system weight.

Now, the system level requirements from the customer (typically driven by his Operational (and Threat) Analysis) include: Performance Requirements (including mission profile), Speed, Deck Motion, Mission Equipment, Endurance, and Crew numbers.

In addition to these there will be a number of Mandatory Requirements (sometimes driven by policy, and sometimes specific to a particular Capability), which have to be addressed. These may also be known as Key Performance Parameters or KPPs.

Examples of candidate KPPs could include

- Crashworthiness,

- EMC and EMP protection,

- Sonar and radar system performance,

- Engine failure criteria (e.g. an engine failure at a critical point during take-off must not result in jettison of weapons or stores on the ship deck)

- Ship deck & hangar size (must be able to operate from a Type 23 ship’s deck and be stowed in a Type 23 hangar

- Environmental (operation in specified environmental conditions – wind, temperature, icing conditions, sea state, deck motion, etc.

- Crew numbers and anthropometry

- Mission profile and endurance

- Weapons and defensive aids fit and capability.

Impact on Design

A further constraint for EH101 (in the early design stage) was the desire to be able to deliver a helicopter with civil certification at the same time as the proposed military utility and naval variants. To meet project timescales, this required that the helicopter make use of an existing engine that was either already certified or on track to so being. (This is because the development and certification of a new engine in parallel to a new airframe would result in unacceptable programme timescale, performance and cost risks).

The mission capabilities for EH101 were expressed in terms of a mission endurance of some five hours with a certain number of crew, plus search radar, sensors, communication equipment, defensive aids and weapons. This mission profile and equipment and crew requirements indicated, via the feasibility studies, a take-off mass of some 13 tonnes (some 33% heavier than the Sea King).

This blog needs donations to carry on to, please donate here to keep us independent. We need your donations to keep this labour-intensive lunacy going.Â

There was, however, a mandatory requirement (KPP) that the new helicopter be compatible with the existing Type 23 Frigate landing deck and hangar size. This restricted the rotor diameter essentially to that of the existing Sea King.

With a given rotor diameter, the power required for a helicopter to hover depends on its all-up weight raised to the power 1.5. This implies that a helicopter 33% heavier than the Sea King, with the same rotor diameter, will require 54% more power to hover under the same conditions.

A quick review of available certified engines reveals that three CT7s (or RTM-322s) providing a total 5,100 hp would meet this requirement, compared with the 3,320 hp of the two Gnomes in the Sea King. The need for three engines emerges from these factors, not from any design criteria placed at the outset by the customer.

Of course, by the time a procurement contract is written, the associated Specification will be written around the selected solution and reflect the use of three CT7 engines.

Is this an optimum solution?

The answer to this is both yes and no.

Whereas, on narrow cost and complexity grounds, the three-engine solution would probably not be favoured, a properly constructed COEIA (combined operational effectiveness and investment appraisal) would probably show that it is justified.

This is primarily because the alternative solution (using a pair of newly-developed 2,600 hp engines) would incur significant additional up-front cost, timescale and performance risk, in parallel with the required airframe development.

In this case, the Type 23 ship deck and hangar are analogous to the possibly apocryphal size of the aircraft carrier lift to suit a Seafire.

It also demonstrates that KPPs are capable of driving a design in a particular direction irrespective of the results of any Operational Analysis.

(Although, to be fair, the mission equipment (sensors, weapons and defensive aids) and their performance, mission profile, crew numbers and environmental requirements are probably all driven by appropriate OA and Threat Analysis).

I should say that I did not participate at this level in the EH101 projects, although I was on the Configuration Team of NH90 during its Feasibility and Pre-Definition Study (up to the point where the UK Government withdrew from the programme). –– Former Head of Future Projects at Westland Helicopters, Dr Ron Smith